FAQs

ABOUT ATOMSTACK

AtomStack is a company deeply committed to crafting cutting-edge intelligent products. Our main thrust lies in producing top-notch laser engraving machines, fiber laser marking machines, 3D printers, and a comprehensive range of laser-related components, accessories, and software. In the future, AtomStack aims to continue its efforts to make personal intelligent manufacturing devices accessible to a global audience and is committed to creating even more outstanding products for the benefit of society.

AtomStack is based in Shenzhen, China. In addition, to ramp up delivery speed, broaden market potential, and deliver streamlined after-sales support, we've set up international warehouses in the United States, Germany, and the Czech Republic. This approach empowers us to better cater to customers across diverse regions.

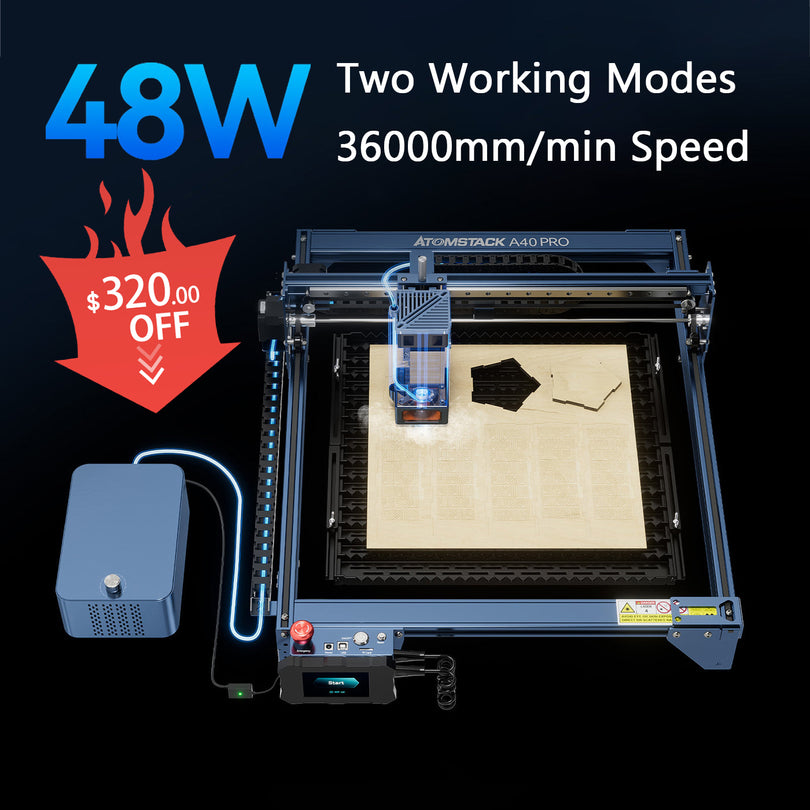

AIR ASSIST

The air assist serves three key functions: it clears the cut for deeper beam penetration, cools the cut edges to prevent plastic sagging and re-welding, and ultimately, it prevents smoke and particles from settling on the lens.

Upgrading the air assist system can ramp up cutting and engraving speeds, elevate overall quality, and shield optical components from the effects of smoke and dust. It can minimize scorched edges, resulting in more uniform engraving tones and crisper image details. Additionally, it provides cleaner and more even edges for cut objects.

BEAM ALIGNMENT

Our laser comes equipped with a standard red cross-positioning module, enabling faster and more precise positioning of the engraving area and determining the material's flatness. The advanced infrared cross-tracking system provides highly detailed and real-time visualization of the laser beam trajectory, making precise fine-tuning of its position easy and straightforward.

HONEYCOMB LASER BED

The honeycomb grid is made of steel. In contrast to its aluminum counterparts, this unit provides the option to secure materials using strong magnets to prevent movement during cutting or engraving.

The honeycomb laser bed is specifically tailored for laser cutting systems. Its open design efficiently filters cutting smoke, minimizing staining and charring when working with wood and other organic materials. It also prevents over-burning, leading to fewer burn marks and cleaner cuts. This significantly enhances cutting efficiency and overall quality.

Sure thing. The honeycomb bed is removable.

EXHAUST

The necessity depends on where you have the laser machine installed. If it's in an enclosed space, investing in an air purification system could be beneficial. However, if you're operating outdoors or in a garage, it's less likely that you'll need to upgrade any type of exhaust system, as you can directly vent the fumes outside.

This is likely because you may not have waited long enough for the built-in exhaust fan to completely clear the smoke through the exhaust duct. The built-in exhaust fan is designed to clear the smoke from the enclosure within 18-30 seconds after the job is finished.

If you're unable to vent the fumes outdoors, or you're working with materials that produce a significant amount of fumes, it's recommended to invest in an air purifier.

The AtomStack safety shell is made of high-quality acrylic and holds an FDA Class 1 certification, ensuring safety. It effectively filters out blue light and comes equipped with a built-in exhaust fan and exhaust duct to quickly disperse smoke, dust, and sparks. The high-resolution camera enables visual processing and creative tasks, including AI-assisted batch processing. Its distinctive deep orange design and dual LED lights ensure clarity during the engraving process, enhancing overall safety.

FOCUS

For your convenience, we provide three adjustable focus blocks.

Choose based on whether you're engraving or cutting. You can easily adjust the height of the laser module in three simple steps. Just loosen the screws on the laser module, slide it until its protective cover contacts the focus block, and then tighten the screws.

It depends on personal preference.

Focusing the laser isn't difficult but it can be intimidating. If the idea of focusing the laser makes you nervous, you can opt for automatic focus; however, after getting familiar with the machine, taking some time to learn how to manually focus your machine can be very helpful.

Yes, our machines are designed for DIY upgrades, allowing you to choose the laser power that suits your needs: 6W, 12W, or 24W. You don't need to replace the entire machine; simply switch out the laser head. Choose ATOMSTACK for a comprehensive range of accessories.

The second-generation packaged blue laser has a larger heat dissipation area, extending its lifespan. Utilizing blue semiconductor laser technology, the lifespan can reach up to 20,000 hours. Excellent control algorithms reduce vibrations and prolong the lifespan of the motors.

Lenses with different focal lengths serve different purposes.

Shorter focal lengths excel in providing higher detail for cutting and engraving, while longer focal lengths are highly effective for cutting thicker materials. You can choose the laser lens that suits your specific needs and requirements.

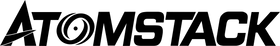

MACHINES

Select a laser engraving machine based on your application needs, considering factors like power, worktable size, focus type, mounting type, material compatibility, software support, user interface, maintenance requirements, and budget.

Absolutely, the laser engraving machine is equipped with four-way limit switches, UV-filtering safety goggles, and a tilt sensor with a 15-degree alert function to ensure safety. It's crucial to follow the manufacturer's guidelines, wear protective gear, and adhere to proper safety operating procedures.

Yes, it's designed to be beginner-friendly and user-friendly. Additionally, the A6, A12, and 24 PRO laser engraving machines come pre-assembled with minimal installation required. They feature a fully integrated design, eliminating complex assembly demands. You can start your creative projects right away by simply installing the laser module. The installation process is straightforward and hassle-free, making it easy for you to get started. At AtomStack, user-friendliness is a top priority in machine design. However, we also provide instruction manuals, user-friendly control panels, and technical support for additional assistance.

Yes! We recommend removing non-fixed components from the machine or securing them before tilting.

Yes! You just need to download the software, and you can operate the software and machine without an internet connection.

Yes, with our advanced auto-power-off recovery system, your engraving experience is enhanced. This smart feature not only remembers the precise engraving position but also employs rapid algorithms for quick repositioning, seamlessly resuming from the exact pause point, ensuring uninterrupted and efficient production. With this innovative solution, you can easily streamline your workflow and save on material costs.

Yes, the AtomStack A24 Pro laser cutting machine features the latest all-aluminum integrated design and dual-axis linear guide rail structure, requiring no installation. The newly added power-off recovery feature prevents unexpected power outages from affecting your work. Improvements include enhanced engraving and cutting speeds, advanced color engraving technology, and the addition of limit switches for more precise positioning.

MATERIALS

This versatile laser cutting and engraving machine can be used for millions of DIY projects based on hundreds of materials, such as plywood, hardwood, metal, leather, glass, paper, dark acrylic, fabric, and more.

You can find your laser machine user manual in our Firmware and Manual Download page.

Speed and power settings will vary depending on the machine you're using and the material. For example, a 20W laser engraving machine can cut thicker materials and is excellent for color engraving on metals. A 5W laser engraving machine is suitable for precision engraving, while a 10W machine supports both engraving and cutting (able to cut 6mm plywood in one pass). Consult our user manual for more information on Material Setting.

Please refrain from using our machines to engrave certain materials, including those containing chrome, PVC, beryllium oxide, and any materials containing halogens, epoxy resins, or phenolic resins.

Absolutely! You can use the Atomstack R1 PRO laser engraving machine with the rotary drum kit to engrave objects with curved surfaces, such as travel mugs, cups, baseball bats, and more. Unleash your imagination and bring your creative ideas to life.

Try obtaining a legitimate license for LightBurn.

OPTIMIZATION

We offer a range of accessories to upgrade your laser machine based on your individual needs. These accessories include air assist, honeycomb bed, enclosure, automatic Z-axis, and more.

To engrave multiple parts simultaneously, aim to minimize the number of changes in direction for your laser head and the overall travel distance. Arrange your items in a pattern that reduces the need for frequent alterations in the path.

PARTS

In the product listings for each item, we provide links that will guide you to the correct page for your machine based on your needs. You can find these links in the additional information for each product. You can view or download the software and manuals on our Firmware and Manual Download page.

For replacement parts not available on the website, please send an email to support@atomstack.com with photos of the serial number on your laser machine, photos of the part itself, and a description. Make sure to include your original order number and current mailing information.

ROTARY AXIS

We offer three different models of rotary drum kits, namely R1, R2, and R3, designed for different shapes of bottles with distinct advantages. R1, R2, and R3 cater to different needs; R1 is suitable for cylindrical engraving like cans or irregular objects, while R2 fits various standard bottle sizes. R3 PRO adds support columns for engraving irregularly shaped cups, like goblets. For more information on which rotary attachment suits you best, including setup, please refer to our blog or the Rotary Roller section on our website (atomstack.com).

In fact, they are all fairly straightforward procedures. If you want to use the rotary axis, you can remove the honeycomb bed, place the rotary set only (do not place it on the rotation button), adjust the focus, and then you can start engraving or cutting.

Please rotate the position of the rotation on the workbench by 180 degrees.

SHIPPING, WARRANTIES AND REFUNDS

Yes, we ship all over the world. Shipping costs will apply, and will be added at checkout. We run discounts and promotions all year, so stay tuned for exclusive deals.

The shipping fee depends on your delivery address, which is determined by the buyer information you provided. Please check the checkout page for the shipping fee.

If you face any difficulties while using our products, feel free to reach out to us at support@atomstack.com. Please include a photo of the serial module on your laser, a photo of the part itself, and a description for our reference. If possible, provide video evidence of any malfunctions through your preferred file-sharing site. Don't forget to include your original order number and your current shipping information.

The total time includes both the processing and delivery times.

Processing time: This is how long it takes to get your item(s) ready to be shipped from our warehouse. It involves preparing the items, conducting quality checks, and packing for shipment. This process typically takes 2 - 3 days.

Delivery time: This is the duration between when your order is shipped and when it's delivered to you. Once your order is dispatched, the delivery time is entirely in the hands of the courier service.

On average, shipping will usually take around 3-7 business days after fulfillment. However, unforeseen delays may occur, and in such cases, shipping could be expected to be delayed by up to 14 business days.

For pre-sale items, please refer to the announced shipping date on our website.

Once your order is confirmed, you will receive a tracking code within 72 hours. Please copy and paste this number into the assigned carrier's website (i.e. DHL, UPS, FedEx, etc.) or just track your order here.

Typically, you can expect to receive a confirmation email along with the tracking number within 72 hours of placing your order. If you have any inquiries, feel free to reach out to our customer support at official@atomstack.com.

Yes, we do! Presently, we provide a 1-year warranty covering all machines, machine parts, and hardware. For further details on the warranty, please refer to our Warranty Policy.

The warranty for AtomStack's refurbished products is three months.

If you wish to request a return, refund, or exchange, and if you need further clarification or have any questions, please feel free to reach out to us via email at official@atomstack.com. We will keep you informed about the status of your return through Email, assuming we have your contact information on record. Please note that refurbished products are not eligible for return or exchange.

In order to be eligible for a refund, you have to return the product within 30 days of your purchased item(s) was delivered to you. If the product is damaged in any way, or you have initiated the return after 30 days have passed, you will not be eligible for a refund.

In order for the product to be eligible for a Refund, make sure these conditions are met:

- Product must be returned in its original packaging

- Product must have the receipt or proof of purchase

After we receive your product, our team of professionals will inspect it and process your refund. The money will be refunded to the Original Payment Method you’ve used during the purchase within 2 - 7 business days after returning has been processed.

For more detailed information regarding our return policy, please click here to view.

MAINTENANCE

- The laser module has a normal service life of over 20,000 hours. However, the operating environment can affect both its lifespan and engraving performance. If you notice the laser module lens turning yellow or becoming blurred, it should be cleaned appropriately.

- Periodically inspect the snugness of the pulley and the profile.

- Routinely examine the belt for any notches. During installation or other processes, avoid bending the belt. It contains steel wires, and bending can potentially cause wire breakage.

SOFTWARE AND MANUALS

You can directly download the software for your laser from our website (click here).

The AtomStack laser engraver is compatible with a range of well-known engraving software. Experienced users can opt for LightBurn, while beginners may prefer LaserGRBL. LaserGRBL is compatible with Win 7/Win 8/Win 10/Win XP, while LightBurn can be used with Windows, Mac, and Linux systems. Data transfer can be done through Wi-Fi, USB cable, and SD card.

In Lightburn, verify if the GRBL version of the device was installed correctly during the installation process. Go to the Laser window, click on Device, select your device, then click on Edit. Ensure that GRBL is selected.

Using LightBurn or LaserGRBL, you can establish direct communication with the laser through a cable. If you have a display board, you can transfer files to a USB and operate the laser through the display board. Additionally, you have the option to engrave or cut using our dedicated app on your mobile phone.

Use the "Start from: Absolute coords" option in the Laser window. Be careful where you set "Job origin" if you choose other work options. Find detailed explanations of how it works in LightBurn's Help.

Attempt to refrain from operating the laser at full 100% power to prolong its lifespan.

Our measurements are conducted in controlled laboratory settings, utilizing a pristine lens and regulated environment. Using higher power levels escalates the chance of lens damage upon contact with combustion byproducts. These byproducts may reflect the diode-generated beam, disperse light radiation into the lens, leading to overheating and potential cracking.

TECHNICAL SUPPORT

- Ensure that you've turned the safety key and confirmed there's voltage in the laser (check if the operation indicator light is on).

- Verify if you've installed the recommended USB port drivers from the manufacturer. Sometimes, during the OS installation, generic drivers are selected, which may not support the functionality of certain connected devices. It's crucial to install the recommended drivers for your computer from the manufacturer's official page.

- Have you installed the CH340 driver? Regardless of your operating system, ensure you install this driver; otherwise, the laser won't operate within normal parameters. For Windows users, upon installing the LaserGRBL program, you'll gain access to the latest version of this driver.

If Windows automatically installed a generic driver for your laser, install the LaserGRBL program, uninstall the driver, and then reinstall it. (Tools => Install CH340 Driver) - Double-check that you've selected the correct COM port and confirmed that the Baud Rate is set to 115200.

- If you're using a Mac computer, you might require a Type-C to USB converter to connect the cable.

Normally, the lasers do not come with an air pump and dust fan as they are sold separately. If you need them for your laser, you can also find them in our product listing.

If you're experiencing a decrease in burning power after connecting the laser to the computer, consider the following:

- Verify the cleanliness of the lens. It's important to check and clean the lens regularly, as burning can release fumes and combustion byproducts that may adhere to the lens. Use the provided cloth along with isopropyl alcohol or specialized photo lens cleaning products. Avoid using cotton-tipped Q-tips as they can scratch the lens due to the hardness of the cotton thread.

- Confirm that "S-value max = 1000" (in LightBurn => Edit => Device Settings) and $30 = 1000 (LaserGRBL => Grbl => Grbl Configurations, or LightBurn => Edit => Machine Settings).

Please be aware that achieving clean-edged cuts (without scorching) and making precise cuts involves employing multiple passes with higher speed and power, approaching maximum but not at 100%, along with the use of air assist. This method allows for cutting in incremental layers without scorching the material deeply. When calculated, the execution time may be equal to or even less than if you were to opt for very low speed and high power.

- The materials used may have an inhomogeneous composition. The plywood may have knots or glue in larger quantities inside, which make burning with the laser beam difficult. The more layers the plywood has, the greater the possibility of encountering a knot. Manufacturers must also use lower-quality wood sheets, which are hidden in the inner layers. Plywood for hobby, special plywood for laser; even if it is more expensive, it is of better quality from this point of view. Try to burn the project one more time, without moving the material, to have complete cuts.

- If there are problems cutting on a larger surface of the material, check if the material was at the same height level with the laser head.

Absolutely, you can choose to replace the laser module with a different one. However, please note that not all machines are compatible with module replacement. For specific details, please refer to the product information provided. Alternatively, you can reach out to us at support@atomstack.com for consultation, and our team of skilled technicians will be happy to assist you.

Yes, auto focus can be added to a manual focus machine.

The Z-axis adjuster needs to be purchased separately. You could find it from accessory product list.

We offer an Extension Kit for AtomStack laser engraving machines. The A6 series products will be upgraded to a conveyor belt.

WATTAGE AND POWER

Laser machines with higher wattage often come with larger bed sizes to accommodate the larger physical dimensions of the higher wattage laser tubes. These tubes are typically longer, so having a larger cabinet to enclose them is practical. With more space in the cabinet, there's room for larger bed sizes, enabling the engraving or cutting of larger materials or multiple parts simultaneously. This offers users greater flexibility and capability when working with higher wattage laser machines.

No, that's not accurate. It's actually easier on a lower-power machine. These machines come equipped with a short focal length lens, whereas higher-wattage machines are equipped with a medium focal length lens. Moreover, lower-power machines offer greater flexibility with power settings, making it easier to achieve a high-quality etch or engrave.

ADDITIONAL INFORMATION

When compared to other cutting equipment, laser cutters and engravers are much safer to use. They generate less dust, emit weaker light, and produce less noise. Nevertheless, it's crucial to wear safety glasses and follow the proper precautions during your work.

We have relevant videos readily available on our website, YouTube, and Facebook Group. Our store is constantly updated with holiday projects, special occasion gifts, and more.

You need eye protection when the hood is open. All Monport laser engravers come with laser protective eyeglasses.

If you are a customer from Amazon or eBay, please reach out to support@atomstack.com.

This depends on the model of your machine. Most of our Laser Engravers that use LightBurn are compatible with MacOS, Windows 10, or 11 and higher.